Digital Fabrication Lab

Los Angeles Campus

The Digital Labs house a multitude of automated tools to perform both subtractive and additive manufacturing processes.

Laser Cutting

The mid-sized cutting systems are purposed for cutting and etching plastics, papers and fabrics. Laser cutters are commonly the first machine introduced to students and quickly become a strong companion to any design development. Continue to the Laser Cutters page for material recommendations, machine restrictions, a template file, and video guides.

Epilogue 36EXT

50 Watt Single CO2 Laser

Bed Size: 36″ x 24″

Universal 12

75 Watt Single CO2 Laser

Bed Size: 48″ x 24″

Universal 9

75 Watt Single CO2 Laser

Bed Size: 36″ x 24″

Laser Cutting Operation Details

For students in the Arch. or I. Arch. programs, the lasers are used for the quick production of working models and the creation of physical presentations. The Laser Cutting orientation provides instruction on how to use the machines but does not address the practice of translating 3D designs to flat material assemblies. We suggest seeking out and referring to packaging design, cut/scored folded paneling, and stacking and interlocking slices.

In the Arch. or I. Arch. programs, etching (explained below) is of little to no use as it is of a more graphic producing operation but occasionally is useful.

1. Completion of Laser Cutting orientation.

2. Proficiency in a 3D modeling.

Laser Cutters are able to perform three types of operations. Sheet material can be CUT, SCORED or ETCHED. The cutting or scoring operations fire the laser and move along a CAD vector drawing. In order to burn graphics into a material, an etching operation is performed.

CUTTING / SCORING

WOOD

Luan Ply (1/8″max)

Cork (1/8″max)

MDF (1/8″max) chars edge

PAPER

Card Stock

Museum Board

Micro Board

Cardboard (no double ply)

PLASTIC

Acrylic/Plexiglass (1/4″max) at slow speeds

Delrin

Mylar (no gold coating)

Styrene (0.04″max)

TEXTILE

Cloth

Felt

Hemp

Cotton

OTHER

Leather

Rubber

EVA Foam

Magnetic Sheet

ETCHING

All the above materials can be etched.

OTHER

Glass

Ceramic Tiles

Anodized Aluminum

Marble, Granite, Soapstone, Plaster

There are many materials that are unsafe to attempt to laser. The list below outlines the most important materials to avoid and why. If a student is unsure if a material can be laser cut, they should consult a Making Complex staff member.

BANNED

PVC -makes Chlorine gas

ABS -makes Cyanide gas

HDPE -melts and becomes gooey

Polystyrene Foam -flammable

Polyurethane Foam -flammable

Epoxy -makes Cyanide gas

Fiberglass / Carbon Fiber -makes Cyanide gas

Fiberglass / Carbon Fiber -makes Cyanide gas

Food -machine internals are not sterile

Vinyl – makes Chlorine gas

Corrugated cardboard – easily flammable

Pleather (faux leather) – makes Chlorine gas

Lexan – flammable

Coated Carbon Fiber – flammable

Mirrored or Reflective-finished material – damanges machine by reflecting laser

Flame-retardant materials – Bromine will create toxic gas

Teflon – melts and releases Polymer fumes

All users must check in with a staff member before starting their work session.

MUST CHECK IN PRIOR TO CUTTING

Students are allowed to make appointments to a maximum time of 1 hour per day and 3 hours per week. This system is on the honor system so do not take advantage of your classmates.

MAX APPOINTMENTS: 1 HOUR/DAY 3 HOURS/WEEK

At the end of one’s appointment, the machine must be stopped. The appointment schedule is not flexible so practice proper time management.

TRASH MUST BE REMOVED FROM MACHINE AND DISCARDED

Staff do not make cuts or clean up after students.

Proper machine setting for the user’s operation must be tested before running their actual job.

STAFF ARE NOT RESPONSIBLE FOR RECOMMENDING SETTINGS

Once the laser is cutting the user must stay with the machine and watch for a flame. If a flame is seen, report to a staff member.

USER MUST STAY WITH MACHINE UNTIL JOB IS COMPLETE

3D Printing

The lab also makes use of eight rapid prototyping machines for on-demand printing of models. They offer many different material options, from plastics to powders and ceramics. Continue to the 3D Printers page for material recommendations, machine restrictions, a template file, and video guides.

Project CJP 660 Pro

Material: gypsum powder

Build Size: 10″ x 15″ x 8″

Support: self support

Colors: CMYK

Character: precise but fragile

Cost: $10 per cubic inch

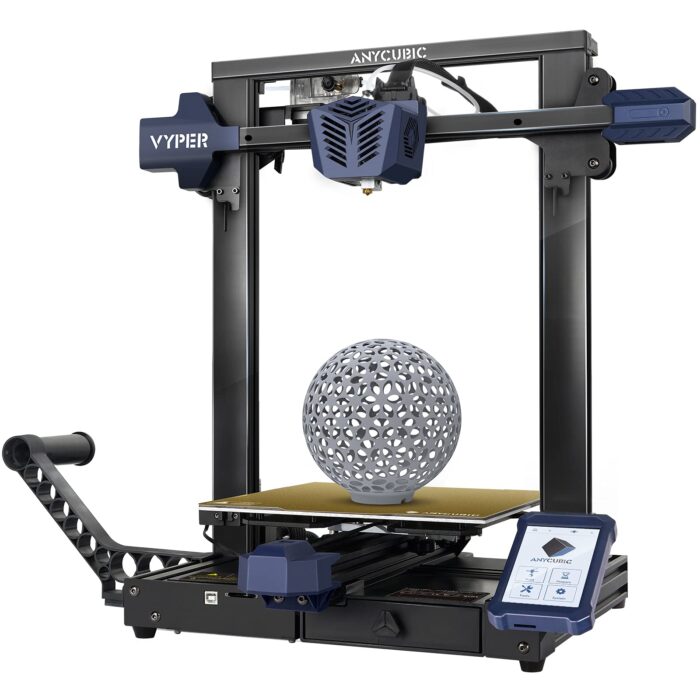

Vyper

Material: PLA

Build Size: 9″ x 9″ x 10″

Support: break away

Colors: White

Character: precise and inexpensive

Cost: $3 per cubic inch

UPRINT SE+

Material: ABS Plastic

Build Size: 8″ x 8″ x 6″

Support: soluble PVA

Colors: Black, White

Character: very precise and soluble support but slow and expensive

Cost: $10 per cubic inch + $5 tray

CLAY PRINTER – image coming soon

Material: ceramic clay

Build Size: 22″ x 22″ x 32″

Support: none

Colors: n/a

Character: inexpensive but extreme striation and limited to self supporting

Cost: $0

3D Printing Operation Details

In the academic arena, 3D printers are used to quickly prototype parts or models with complex geometries. As a student, one will seek out the use of these machines when a project cannot be satisfied by quicker or cheaper means. Another use, as seen with the clay printer, is the investigation of such technologies and their implications to the field.

1. File Submittal

2. 3D Printing Consultation

3. Proficiency in 3D modeling.

FILE PREPARATION

model scaling > wall thickening > closing geometry > converting to .STL

PRINTING FILE

prepare file > print and fill out form > make appointment > put into print queue > pickup print

The Making Complex offers digital file submissions for the 3D Printers and CNC Routers.

All students intending to 3D print must prepare their own geometry, fill out the submission form and make an appointment.

NO FILES WILL BE ACCEPTED WITHOUT AN APPOINTMENT AND FORM

It is the student’s responsibility to submit watertight and properly thickened models. The Making Complex takes no responsibility for failed prints due to geometry.

All submitted files are printed on a first come, first served basis. Once your consultation is complete your form is placed into a queue. When the print is complete, you will receive an email notifying you of its status.

PRINTS ARE RUN ON A FIRST COME, FIRST SERVED BASIS.

The Making Complex staff cannot guarantee that your print will be ready on a certain day/time.

If multiple files are submitted during the same consultation, yours will be run first, then the next person’s print will be run and then your second file will be run and so on.

To students needing to run multiple files on the UPrint SEplus, we advise you to print outside of the university. Refer to our Resources page for recommendations.

CNC Routing

Each campus has a large format 3 axis CNC router capable of processing plywood, plastics and foams. From cutting out flat shapes to assemblies and 3D surfacing of thick stocks. Continue to the CNC Routers page for material recommendations, machine restrictions, a template file, and video guides.

Techno LC4896

Bed Size: 48″ x 96″ x 5″

Auto Tool Changer & Vacuum Bed

Capabilities: Profiling, Engraving and 3D sculpting

Cost: $15 per hour ($15 minimum)

Laguna SmartShopII

Bed Size: 48″ x 96″ x 5″

Auto Tool Changer & Vacuum Bed

Capabilities: Profiling, Engraving and 3D sculpting

Cost: $15 per hour ($15 minimum)

CNC Operation Details

CNC routers have long been a digital tool used in the academic setting of design. The machine has the ability to quickly mock up full scale prototypes, make highly detailed site models and sculpt molds for casting parts. The learning curve is steep but once the nature of the process is understood, students find it incredibly useful.

1. File Submittal

2. CNC Consultation

3. Proficiency in 3D modeling.

CNC Routers are used to cut out flat shapes (Profiling) such as gears and screens or making reliefs (2.5D sculpting) such as molds or topographies.

FILE PREPARATION

import scaled geometry into template file > sett proper layers > follow setup directions in the template file

RUNNING OPERATION

prepare file > fill out form > schedule and show up to consultation > bring material to appointment > clean CNC room

The Making Complex offers digital file submissions for the 3D Printers and CNC Routers.

Maximum material dimensions : 48″wide x 96″long” x 5″thick.

The amount of detail able to be achieved is dependent on tool size and time.

3 axis CNC routers are not able to machine “undercuts”. Refer to guide for details.

WOOD (DRY)

Plywood

MDF (formaldehyde free)

Softwood Lumber

Hardwood Lumber

FOAM (RIGID)

Styrofoam®

High Density Urethane

Precision Board®

Renshape®

Corafoam®

PLASTIC

Cast Acrylic

Sintra®

HDPE

ABS

METAL

Brass

Copper

Aluminum (sheet only)

OTHER

Corian®

Wax

Cork

The list below makes note of the most important materials to avoid. If a student is unsure if a material can be routed, they should consult a Making Complex staff member.

BANNED

Ferrous Metals (steel, stainless steel…)

Extruded Acrylic (plexiglass®)

Engineered woods with formaldehyde

All students intending to use the CNC router must follow the above process.

TEMPLATE FILE AND FORM MUST BE COMPLETE BEFORE CONSULTATION

Staff are not able to perform any of the setup steps for students.

Material brought to the appointment must be exactly what is indicated in the Template File.

Any tool not within our provided library must be purchased by the student.

After a work session is complete the student must clean the CNC room to perfection, even including any mess that is not from their job.

STUDENT MUST CLEAN THE ENTIRE CNC ROOM BEFORE LEAVING THE FACILITY.

Clay 3D Printing

In addition to our collection of production-style 3D printers, the Making Complex has a dedicated machine for hands-on experimentation with extrusion based printing.

CLAY PRINTER – image coming soon

Material: ceramic clay

Build Size: 22″ x 22″ x 32″

Support: none

Colors: n/a

Character: inexpensive but extreme striation and limited to self supporting

Cost: $0

Clay 3D Printing Operation Details

3D printing with clay offers students to opportunity to experiment with additive manufacturing at a larger scale. With the ability to change printing parameters, from material viscosity to layer height and thickness, one can take complete control over the process.

1. Completion of Clay Printing orientation.

2. Proficiency in a 3D modeling.

The Potter Bot 3D Printer has the capacity to print single-shelled self supporting designs.

FILE PREPARATION

simplify design to a single-shelled self supporting design > convert to mesh > export model as .STL

RUNNING OPERATION

prepare file > schedule Clay Printer appointment > check in with MC staff member > run clay printer with occasional staff mentoring.

Maximum build dimensions : 12″wide x 12″long” x 12″thick.

The amount of detail able to be achieved is dependent on extruder tip chosen..

Output quality is dependent on user’s dedication to testing machine settings.

Clay will always be provided to machine users by the facility.

The Making Complex stocks a custom prepared Laguna B-Mix clay.

*B-Mix extrudes smooth and fires to a light cream color.

Machine users also have the opportunity to supply their own material, however, they will not allowed to use the pugmill to prepare it.

Though the Potter Bot can work with any material type with the consistency of clay, the use of self setting materials(e.g. cement) is prohibited.

The following link will send you to our Tutorials page, where one can refresh themselves on the proper usage of any and all machines.

Tutorials

All students intending to use the Clay Printer must follow the above process.

Staff are not able to perform any of the setup steps for students.

Students must stay with the machine during the entire print, to ensure safe operation.

After a work session is complete the student must clean the clay printer room to perfection, even including any mess that is not from their job.

STUDENT MUST CLEAN THE ENTIRE CLAY PRINTER ROOM BEFORE LEAVING THE FACILITY.

Machine setup must performed by the student. One should plan for 15 to 45 minutes of machine setup before printing.

Vacuum Forming

The ability to produce thin-shelled plastic parts is a great addition to the student’s model making toolset.

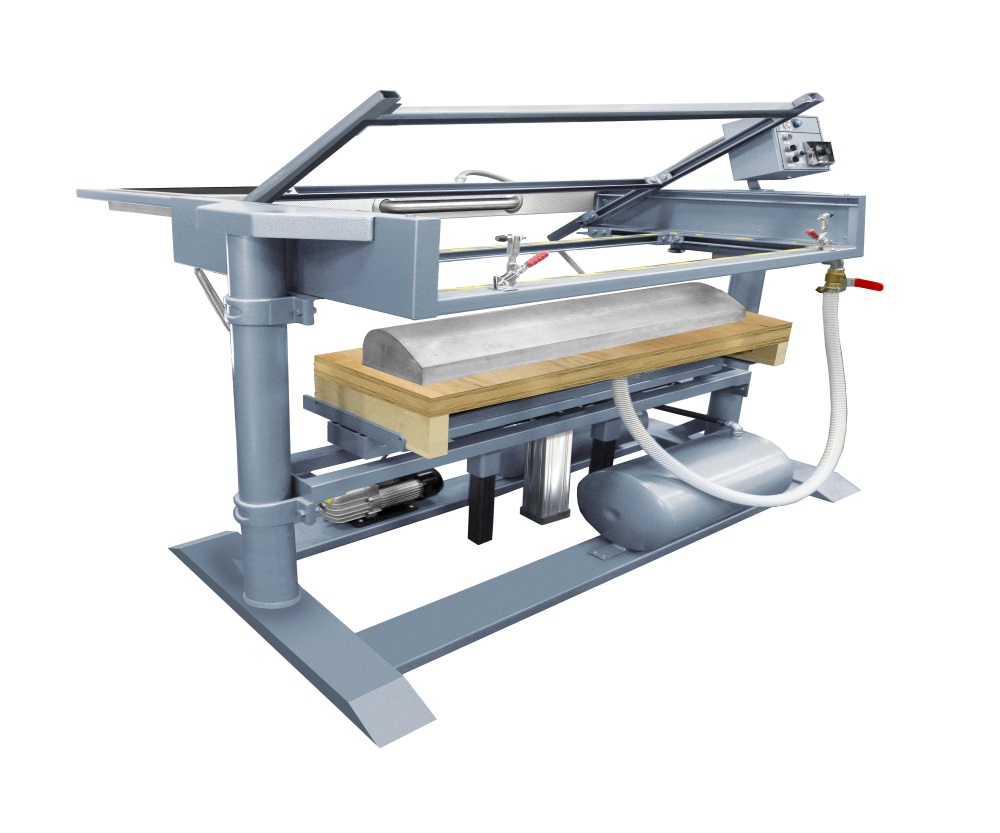

BELOVAC BV C-Class 24×48

Material Size: 24″ x 48″

Max. Mold Size: 16″ x 32″ x 3″

Cost: $0

Vacuum Forming Operation Details

Vacuum Formers offer students the ability to produce thin-shelled plastic parts to be used as presentation model components and quick molds for casting solid objects.

1. Completion of Vacuum Former orientation.

The Belovac has the capacity to heat up plastic films and to pull them down onto custom rigid molds.

MACHINE OPERATION

produce mold > acquire plastic film > schedule Vacuum Former appointment > check in with MC staff member > run machine with occasional staff mentoring.

Maximum part dimensions : 16″wide x 32″long” x 3″thick.

Maximum sheet thickness: 1/4″

ABS

PVC

PET

Styrene

Kydex

Polypropylene

All students intending to use the Vacuum Former must follow the above process.

Staff are not able to perform any of the setup steps for students.

After a work session is complete the student must clean the vacuum former room to perfection, even including any mess that is not from their job.

STUDENT MUST CLEAN THE ENTIRE VACUUM FORMER ROOM BEFORE LEAVING THE FACILITY